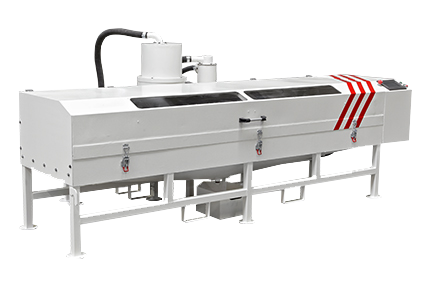

In collaboration with Yenar we have set up the first fully automatic CNC state of the art grooving and sand blasting center at Delhi NCR.

In collaboration with Yenar we have set up the first fully automatic CNC state of the art grooving and sand blasting center at Delhi NCR.

A fully automatic CNC programmed machine is precise & helps in better performance of the roll.

Once you enter the data- such as the number of grooves, dimension of the land and shape of tool- the software is able to calculate the groove depth and, in particular, the product size in the groove. This result helps the miller understand the compatibility of grooves with the production requirements.

a) It prevents rolls from touching before obtaining the required products.

b) 100% accuracy.

c) It has a predefined cutting Depth.

d) We can achieve exact required parameters of Rolls spiral, land, margin, no. of teeth, helical angle and many more things which are required to make a better design of roll for better performance.

Disadvantages of Grooving Rolls manually:-

a) Decrease in Yield.

b) Higher energy consumption.

c) Loss in product moisture.

d) Inefficient grooves mistreat the product, resulting in lower quality flour.